DRMFG precision customized short fiber cutting blade is suitable for Lumus, Barmag, Fleissner, Neumag Zimmer, DM & E and other devices.

The artificial short fiber cutting process has strict requirements for cutting blades. In addition to the service life, there are equivalent requirements for cutting short fiber quality, cutting efficiency, and replacement cycle, and replacement convenience, because this is related to the production efficiency of large equipment assembly line operations.

DRMFG fine -style custom blade for more than 10 years, providing customers with not only high -quality products, but also providing customers with stable, continuous and safe services to customers, becoming a helper of customers‘ efficient production links, helping enterprises operate efficiently, providing enterprises with high cost performances Product and product and

Stable service.

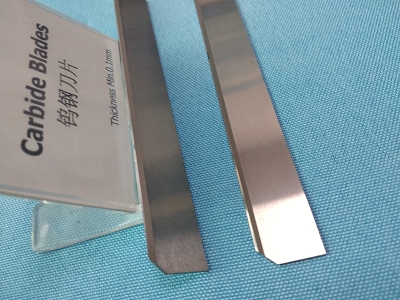

Characteristics of DRMFG Short Fiber Cutting blade Features:

1. Using high -quality hard alloys, wear resistance and good toughness.

2. Customized processing according to the customer equipment type, the matching degree is good.

3. Select the corresponding model according to the type of product.

4. The size is consistent, and the blade is checked.

5. Blade mouth is sharp, there is no gap in the factory

6. Long cut life, the same is 1.5 to 2 times the market for ordinary products in the market

7. Strictly controlling control, good production equipment

8. More than ten years of experience, customer verification quality and stable quality

9. Packaging is safe, convenient for transportation and preservation

10. High cost performance, exports to many countries.

DRMFG custom processing blade is applied to more than 20 industries:

Mainly apply to chemical fiber, electronics, adhesion, film, rubber, aluminum foil, copper foil, lithium battery packaging materials, non -woven fabrics, composite packaging materials, electronic materials, cigarettes, leather, ceramic processing, semiconductor, mobile glass, tape, dry Film, cosmetics,

Pharmaceutical and automated equipment manufacturing industries.

The wear -resistant and long -lasting wear of the person‘s precision blade has improved production efficiency and saved costs.

Our company has customized the specifications:

50*15*0.9mm

80*12*0.8mm

117*15.6*0.9mm

120*16.4*0.9mm

Customer application scene is as follows: